Things To Consider

Important Considerations For Stone Benchtops Edge Profile, Joint Type, Overhang, Slab Size & Sink Cut-Out

It is essential that you decide on the design parameters like edge profile, overhang, sink cut-out and joint type before you finalize the design of your kitchen benchtop (countertop), vanity top, splashback and stone island.

Once the stone has been cut it is generally not possible to alter these parameters at a later stage.

Edge Profile

Joint Type

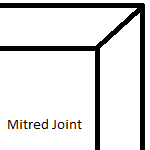

Mitred Joint

Mitred Joint

This type of joining option is recommended for manufactured stone types.

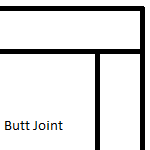

Butt Joint

Butt Joint

This type of joining option is available for all type of stones viz. Manufactured Stone (Caesarstone® and Essastone®), Granite and Marble.

Overhang

It is recommended that the Overhang for bench tops (counter tops) should not be more than 300 mm or 1 foot.

Slab Size

The maximum available size varies from stone to stone. The different sizes that are available are as follows,

3200 mm x 1600 mm – 20% more than standard slab size. This is also called as jumbo size.

3020 mm x 1500 mm – A few selected colors of man made stone are available in this size.

3020 mm x 1400 mm – All varieties of the man made stone are available in this size.

3200 mm x 1900 mm – Most of the natural granite and marble varieties are available in this size. This is longer and wider than the above sizes. Though being natural products the sizes may vary

Sink & Hot Plate Cut Outs

Mount types for sinks are of two types – Top Mount & Under Mount.

Top Mount

The minimum recommended distance between the outer edge of the benchtop (countertop) and the edge of the sink cut-out is 60 mm for Manufactured stones and 80 mm for Granite and Marble.

Under Mount

The minimum recommended distance between the outer edge of the benchtop (countertop) and the edge of the sink cut-out is 60 ~ 80 mm for Manufactured stones and 100 mm for Granite and Marble.